Powerful equipments

The craftsman's mind runs through every strict production step and powerful machine is the guarantee that we can provide the satisfied products to our customers. Alctron manufacturing center owns more than 30 units’ large-scale precision CNC punch press, lathe, drilling machine, engraving and milling, more than 50 units’ ordinary punch, milling machine, lathe, more than 10 units’ injection molding machine, die casting machine. It equipped with processing centers, EDM, wire cutting and other mold processing equipment more than 20 units, realizing from the mold manufacturing to all kinds of metal processing, plastic and metal molding into one-stop processing system.

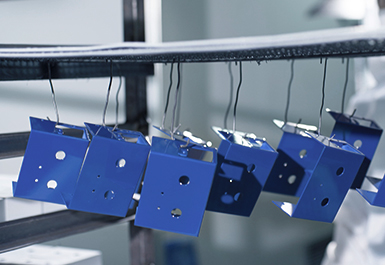

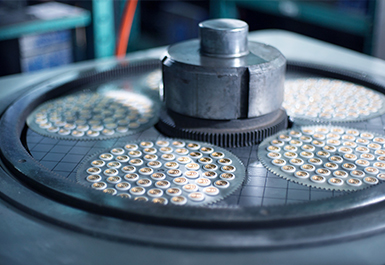

The company has environmental polished equipment, automatic reciprocating machine rotary spray painting lines, painting lines, drencher dust-free paint line, all kinds of screen printing equipment, laser engraving equipment, a total of more than 20 sets. Alctron owns advanced high-speed SMT production line, reflow soldering, wave soldering, plug-in line, assembly line and the corresponding equipments.